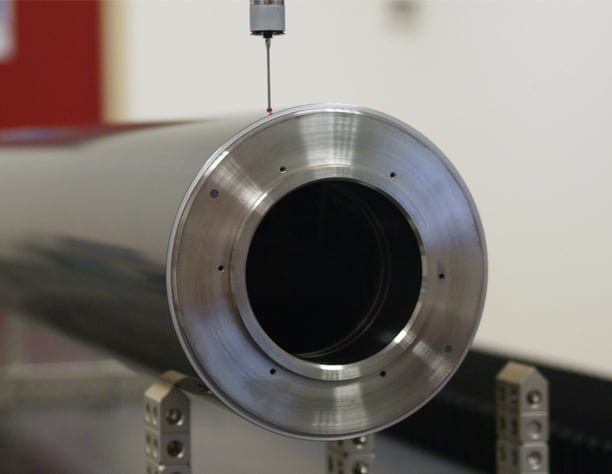

Epsilon Composite designs and manufactures anilox rollers with a carbon fiber composite core for flexographic printing machines machines.

Also called a raster cylinder, this roller is at the heart of the flexographic printing process.

Charged with supplying a measured quantity of ink to the printing plate, Anilox must be precise in terms of volume, screen dot and linearity. However, it is not just that, its dynamic stability and its ability to absorb vibrations/reduce bouncing is now a major challenge for productivity and printing quality.

Epsilon designs and manufactures carbon anilox cylinders and anilox carbon sleeves with hydraulic clamping.

Epsilon carbon Anilox benefit from patented “K1” technology to achieve a stiffness adapted to your printing challenges:

- Free attenuation/suppression of bouncing

- Significant reduction in wear on the blades and ceramic coating of Anilox

- Significant reduction in Anilox weight – ease of handling – compared to steel

The specific design by Epsilon guarantees performance and robustness, and the carbon tube is protected against most daily aggressions (shocks, cleaning agents, etc.). The engraved ceramic coating can be renewed several times during the product’s life.

| CARRIER SHAFT Ø defined by the customer in the case of an Anilox sleeve /Hydraulic clamping | OPERATING TEMPERATURE Up to 60°C |

| DIMENSIONS STORK: up to 1040mm Printing width: up to 2800mm. Other dimensions on request | MAINTENANCE Resistant to conventional solvents used in flexo printing Recommended that isopropyl alcohol is used for cleaning |

| CONDUCTIVITY Complies with the provisions of ATEX 95 | STORAGE/ TRANSPORT Recommended storage in vertical position Protect Anilox from shocks Transport Anilox in the box and on original supports |