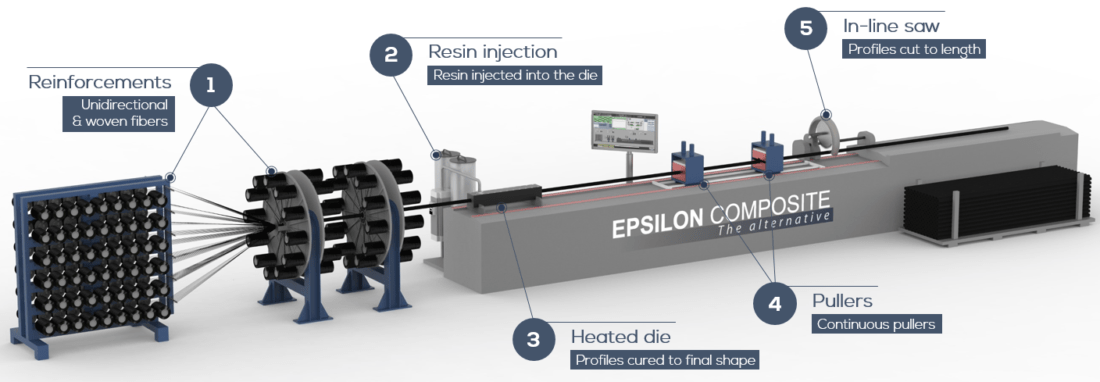

Pullwinding is a variant of the pultrusion process.

On one hand, pultrusion is an automated process that allows the continuous production of high performance composite profiles. On the other hand, with the pullwinding process, carbon fiber is spooled at a required angle.

Want to know more about the pullwinding process ? See our video.

Carbon fiber pultrusion is at the historical core of Epsilon Composite’s work. Since 1987, Epsilon Composite is the world leader of this manufacturing process from its factory in Gaillan Médoc (France).

“Pullwinding” stems from the contraction of “pull” and “winding”. On a pullwinding production line, carbon fiber is impregnated with a resin which is polymerized in a heating die. This gives the tube its shape and final properties. At last, just like on a pultrusion line, the tubes are automatically cut at the desired length.

Pullwinding make efficient and industrial manufacturing at high performance and optimal quality possible :

- A very high fiber rate (60 to 75 % in volume, versus 50 to 55 % for most other composite manufacturing processes),

- A low permeability level (<2% in volume),

- An optimal fiber alignment according to the desired angles (from 0° to 90°),

- An excellent surface appearance which does not require machining or finishing (“net shape”),

- Excellent reproductibility from one production to another.

Moreover, thanks to 24/7 production, this manufacturing process guarantees high yields.

We use spools (carbon, glass, aramid or natural materials) and resin components (base, hardener, accelerator and additives) as raw materials. This insures flexibility and optimized production costs compared to the use of textile fabrics or prepregs.

Thermosets and thermoplastics

According to our experience, thermosetting resins (from the epoxide family) are usually the best compromise for performance, durability and costs in pultrusion. However, it’s also possible to manufacture thermoplastic composite materials in pultrusion. For example, to benefit from better recycling properties or other specific properties (impact or fire resistance, weldability…). From the early 90’s, Epsilon Composite developed thermoplastic pultrusion for the aerospace sector. The compagny continues to innovate and incorporate the latest industry advancements in order to provide its clients with the most suitable materials.