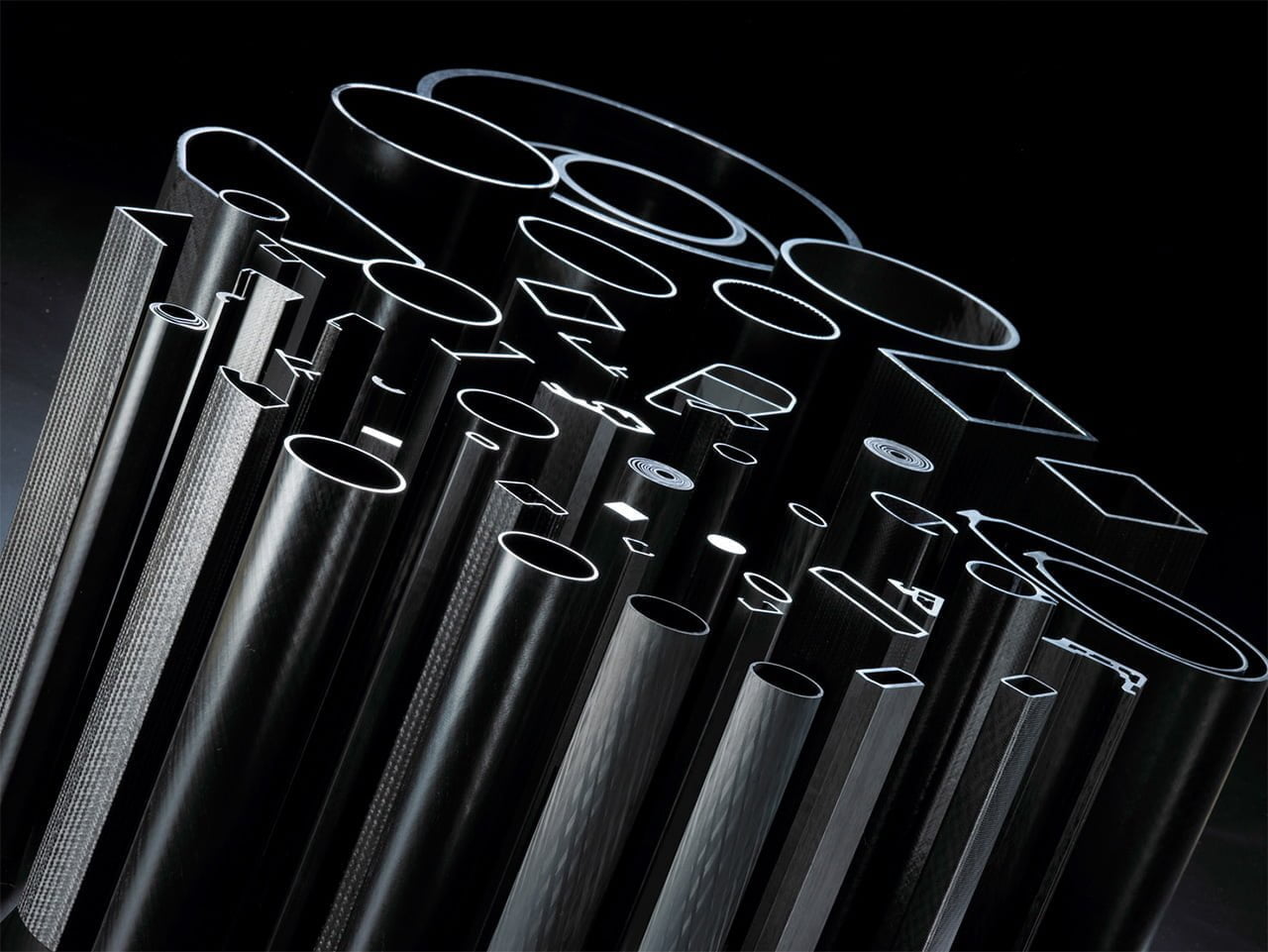

High performance lightweight carbon fiber tubes and profiles made in pultrusion, pullwinding & K1.

Thanks to our industrial manufacturing processes (including Pultrusion, Pullwinding or K1 technologies) and extensive experience in composite materials, Epsilon designs and manufactures lightweight composite tubes and profiles in all shapes (round, oval, square, rectangle, or special shapes) using materials tailored to your needs:

- Epoxy matrix (or other specific resins, as required),

- Carbon fiber adapted to mechanical stresses: High Strength (HS), Intermediate Modulus (IM), High Modulus (HM) or Very High Modulus (UHM),

- Natural fibers (flax, hemp, basalt,…),

- Synthetic fibers,

- Function integration (such as fiberglass or thermoplasic insulating/protective layer),

- Finishing (machining, assembly, non-destructive testing…).

Download our pultrusion & pullwinding standard profiles catalogue (includes standard technical data)

| Tube diameter (Ø) | Manufacturing process | Tensile modulus (E) | Tensile failure stress (σ) | Glass transition temperature (Tg) |

| Carbon tubes Ø5 to Ø40 mm | Pultrusion or Pullwinding | from 90 to 450 GPa | from 1000 to 3400 MPa | from 100 to 220°C |

| Carbon tubes Ø40 to Ø200 | Pultrusion or Pullwinding | from 90 to 450 GPa | from 1000 to 3400 MPa | from 100 to 220°C |

| Carbon tubes >Ø200mm | K1 | up to 400 GPa | from 1000 to 3400 MPa | from 100 to 220°C |

Can’t find what you need? Dimensions? Stiffness? Other tubes and profiles can be specifically developed according to your needs. Contact us !

There is no length limit with pultrusion and pullwinding, as they are continuous precess so we can cut the profiles to the desired length.

For tube diameters above 200 mm (using K1 technology), our standard maximum length is 12 m, and longer on request.