Stiffness + light weight

Lightweight structures with optimal stiffness

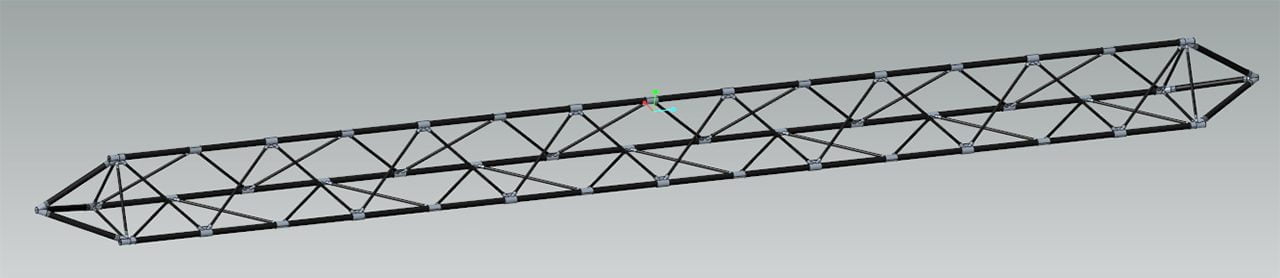

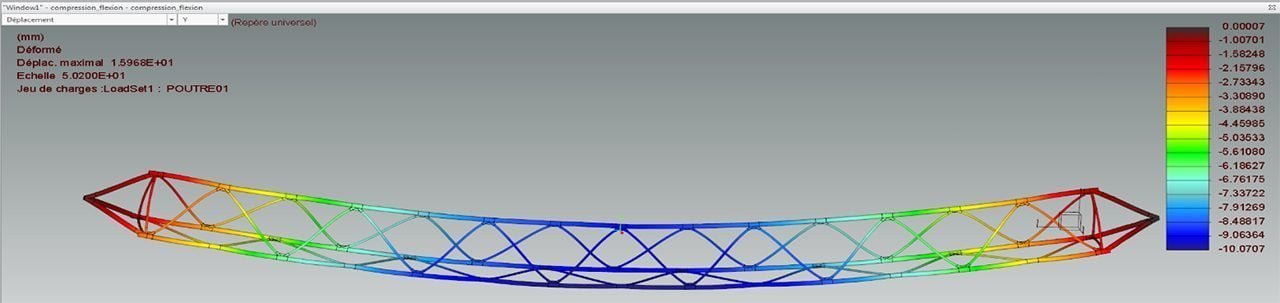

Compared to a solid monolithic beam, truss beams provide a solution with an unparalleled stiffness/weight ratio, thanks to the assembly of standard tubes.

To go even further than existing metal solutions, we have transposed this technology to carbon composite. The tubes are lighter and stiffer than their metal counterparts, meaning it is therefore possible to push the limits with ultra-light XXL structures that are corrosion-resistant.

By applying its experience in mechanical dimensioning (static/dynamic) and structural assemblies, Epsilon Composite offers well-developed solutions to create structural trusses in composite materials.

Technical options

For metallic truss beams, tubes are generally assembled by welding. We have developed several solutions more adapted to composite materials, which meet very specific needs:

- Assembled beams that cannot be dismantled with glued connection parts: these connections can be made from composite or metal and offer the best compromise between weight, stiffness and cost.

- 100% composite beams that cannot be dismantled with overmoulded or draped connections: these solutions can be optimised further in terms of weight, but industrialising them can be more expensive.

- Beams that can be dismantled by connecting rods: solutions that cannot be optimised as much in terms of weight, which makes assembly, transport and repair easier.

We offer several geometries of structural trusses to adapt to your specifications and the available space: 2D “ladders”, triangular trusses, square section beams, etc.

Depending on your requirements (stiffness requirements, weight savings, fire resistance, impact resistance, etc.), our experts will guide you towards an optimised solution.