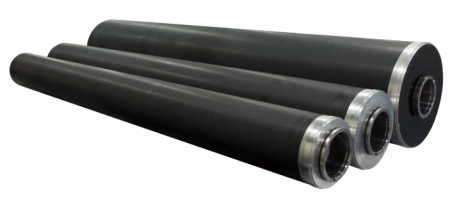

Durable high performance carbon fiber adapters for flexo printing machines

Also known as an intermediate sleeve, intermediate cylinder or interleaf cylinder, the adapter plays a major role in print quality and productivity control

Carbon fiber flexo adapters: a proven design

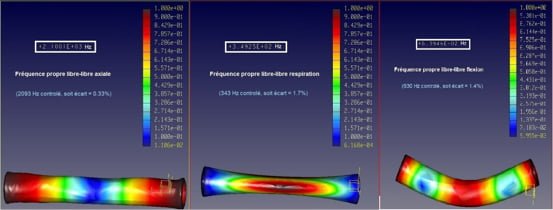

The result of more than 15 years of research, development and technological expertise, the Epsilon “bridge” design, combined with a unique patented process for the production of carbon tubes, makes it possible to achieve unparalleled mechanical characteristics and dynamic stability.

Print tests carried out using adapters of different stiffnesses demonstrate the undeniable influence of stiffness on print quality and productivity.

Only the stiffest adapters (axially and transversely) can meet the requirements of printers:

- Free attenuation/suppression of bouncing

- Reduction of machine downtime

- Reduction of pressure setting times

- Reduction of adjustment times (adhesives, sleeves, plates, etc.)

- Maintain/increase printing speed

Epsilon carries out studies, designs and calculations in-house through to its technical office.

The control and measurement methods used by Epsilon have been specifically developed and adapted to our products (natural frequency measurement and numerical correlation, bending bench, etc.)

The carbon tube: at the heart of the system

Epsilon selects only high and very high modulus carbon fibers and high quality epoxy resins.

The “K1” process, patented by Epsilon Composite, is a unique combination of excellent pultrusion and filament winding that allows the industrial production of small and large series of tubes whose performance (stiffness) can be customised.

Learn more about K1 technology

Clamping on mobile shaft: pneumatic; hydraulic

The Epsilon pneumatic and hydraulic adapters benefit from a common “bridge” architecture and K1 carbon tubes, giving them excellent dynamic behaviour.

Hydraulic clamping is, however, stiffer than pneumatic clamping.

Key Features – Pneumatic adapters

| Ø CARRIER SHAFT Defined by the customer | INDEXATION ADAPTOR/CARRIER SHAFT Removable bayonet support Other systems on request |

| DIMENSIONS STORK. >> 1280mm Printing width. >> 2050mm Other dimensions on request | CONDUCTIVITY Complies with the provisions of ATEX 95 |

| AIR POWER SUPPLY SYSTEM Direct (through the shaft on the operator side) Separated (machine side) Double direct & separated system Other systems on request | OPERATING TEMPERATURE Up to 60°C |

| ASSEMBLY SLEEVE Ball air nozzles Number and position of nozzles can be modified on request | MAINTENANCE Resistant to conventional solvents used in flexo printing Recommended cleaning with isopropyl alcohol |

| INDEXATION SLEEVE/ADAPTER Removable key Other systems on request | STORAGE/ TRANSPORT Recommended storage in vertical position Protect the adapters from impacts Transport the adapters in the box and on the original supports |

Key Features – Hydraulic adapters

| CARRIER SHAFT Ø. Defined by the customer Guide in the adapter >> glass fiber or carbon fiber tube depending on the dimensions of the adapter | INDEXATION ADAPTOR/CARRIER SHAFT Straight groove Other systems on request |

| DIMENSIONS STORK: up to 1900mm Printing width: up to 2800mm Other dimensions on request | CONDUCTIVITY Complies with the provisions of ATEX 95 |

| AIR POWER SUPPLY SYSTEM Direct Other systems on request | OPERATING TEMPERATURE Up to 60°C |

| ASSEMBLY SLEEVE Ball air nozzles Number and position of nozzles can be modified on request | MAINTENANCE Resistant to conventional solvents used in flexo printing. Cleaning with isopropyl alcohol is recommended |

| INDEXATION SLEEVE/ ADAPTER Removable cylindrical pin Removable key Other systems on request | STORAGE/ TRANSPORT Recommended storage in vertical position Protect the adapters from impacts Transport the adapters in the box and on the original supports |