A pharaonic project that has dethroned the renovation of the Westgate Bridge as being one of the largest projects in the history of carbon fiber.

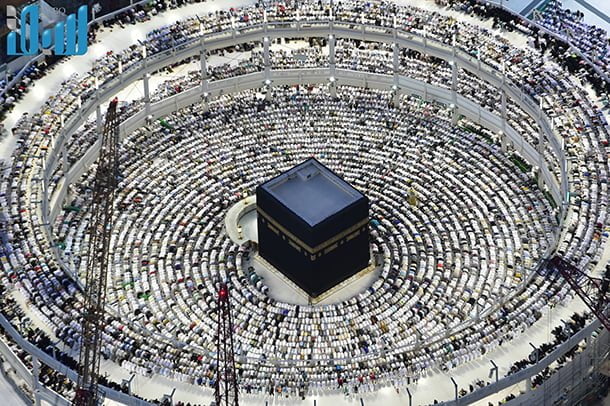

When Saudi Arabia was undertaking the Mataf extension project to absorb the increase in the number of pilgrims to Mecca, the construction of a 7,500 m² dismantlable footbridge was launched very quickly to facilitate the movement of pilgrims and limit the risk of injuries due to crowd movements.

The client: PCT

The challenge: a lightweight structure (so as not to damage the ground of this sacred place), able to support the load caused by the passage of several thousand people per hour.

Solutions provided by Epsilon Composite : carbon was the solution proposed to King Al Saud, who gave his consent on condition that this project be completed in less than 6 months. Epsilon contributed brought expertise and production capacity for the manufacture of giant poles using the K1 process (combining pultrusion and filament winding) to support the footbridge, as well as the pultrusion of Carbolam® flat laminates to reinforce the floor.

The result : 6 months after the launch of the project, thousands of pilgrims from all over the world walked safely over the footbridge floor, made possible thanks to a structure incorporating 70 poles, twelve meters high, and a floor reinforced with several tens of kilometers of Carbolam® pultruded carbon.

Epsilon Composite, as the world leader in carbon pultrusion, inventor of the K1 technology, and with unparalleled production capacities, was the ideal partner for this ambitious project.

All products were made to comply and were on time, and were made using over 100 tons of transformed carbon. This was a great success that enabled the development of other important markets in the future.