Case study: doctor blade chambers for flexo printing machines, made from pultrusion

Date: 2015-20XX

Status: in production

Quantity: large series

Doctor blade chambers are generally between 1m and 3.5m long, used in various printing processes to deliver a calibrated quantity of ink onto a roller.

These parts are traditionally made of aluminum, but Epsilon Composite has developed a carbon fiber version that greatly facilitates machine maintenance (cleaning & handling), prevents ink leaks by eliminating corrosion problems, and improves machine performance and productivity through reduced vibration.

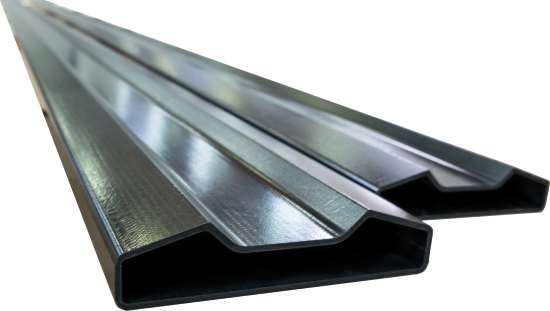

The body of the doctor blade chamber consists of a pultruded profile, custom-designed by our engineering department in collaboration with the Bobst Group, and manufactured by the kilometer in our pultrusion workshops.

The cross-section of this profile allows the integration of all functions on the beam (doctor blades, flange, cleaning system, instrumentation…) while ensuring optimum integration on the machine.

The doctor blade chambers also incorporate other composite profiles, all manufactured by pultrusion, to limit the use of metal parts to what is strictly necessary (such as the stainless steel blade, cleaning nozzles and threaded inserts).

See the doctor blade chamber product page for more information.

[Watch the customer testimonial on this project]