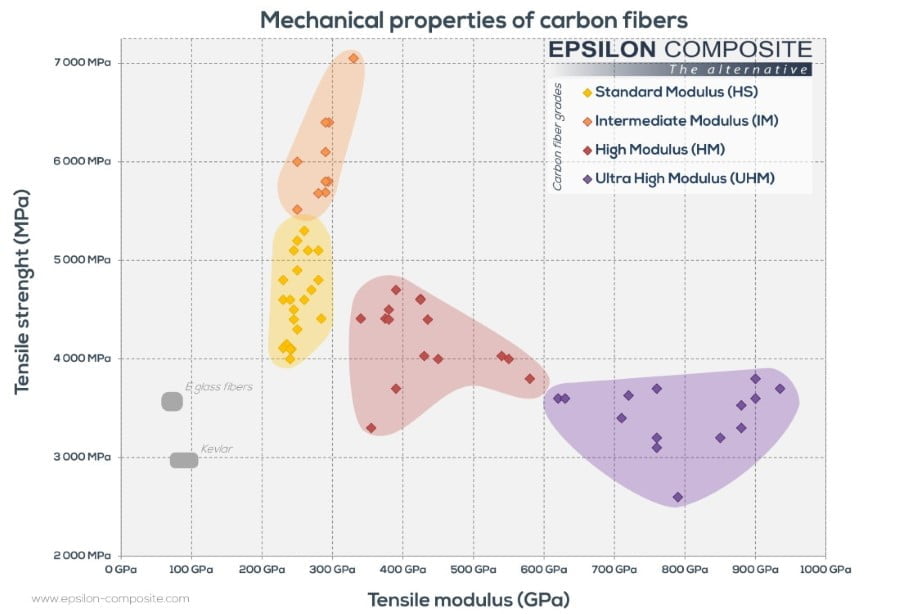

There are various grades of Carbon Fibers:

– High Strength / Standard Modulus (HS), the most common grade

– Intermediate Modulus (IM)

– High Modulus (HM)

– Ultra High Modulus (UHM)

Their tensile modulus range from 230 Gpa for PAN based High Strength fibers, up to 900 GPa for Ultra High Modulus fibers made from coal tar pitch!

Carbon fiber tensile stress can go from 2,500 MPa up to 7,000 Mpa.

Of course, carbon fibers are also extremely lightweight (average density of 1.8), which translates into a 1.6 density for carbon-epoxy composites. This gives composite materials outstanding specific strength (strength to weight ratio), 50x higher than steel.

Among the many interesting properties of Carbon Fibers, it’s also worth noting that their linear coefficient of thermal expansion is close to 0. This guarantees an outstanding dimensional stability, even in the most extreme environmental conditions.

With more than 35 years of experience in carbon fibers, Epsilon Composite engineering teams will select the best materials for your need.

Our promise to you: we will only use the highest quality fibers from the world’s best manufacturers, and never cut corners with cheaper less reliable fibers.