The increase in web widths and print speeds makes the use of rollers and carbon fiber components essential in most printing machines. Lighter and stiffer than traditional metal solutions (steel or aluminum), carbon fiber-based composites improve productivity and print quality by drastically reducing deflection and machine vibrations, while offering numerous benefits in terms of handling, durability, and the flexibility and efficiency of prints, with time savings and reduced waste during each change.

Discover the benefits of our range of carbon fiber products.

Our products are approved by machine manufacturers (OEMs) and have been widely used for over 20 years in various printing processes: flexography, digital, offset, rotogravure, gravure…

Epsilon Rollers manufactures more than 30,000 ultra-rigid and lightweight technical rollers each year thanks to pullwinding and K1 technology.

Epsilon Rollers offers a complete range of technical rollers and machine parts made from carbon fiber to optimize the performance of your printing machines:

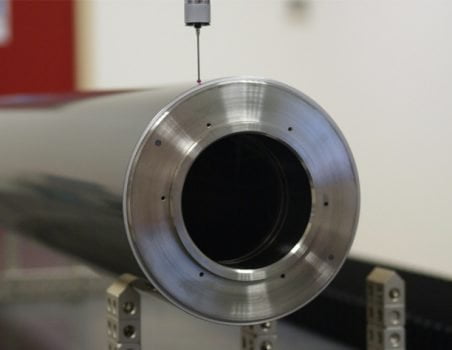

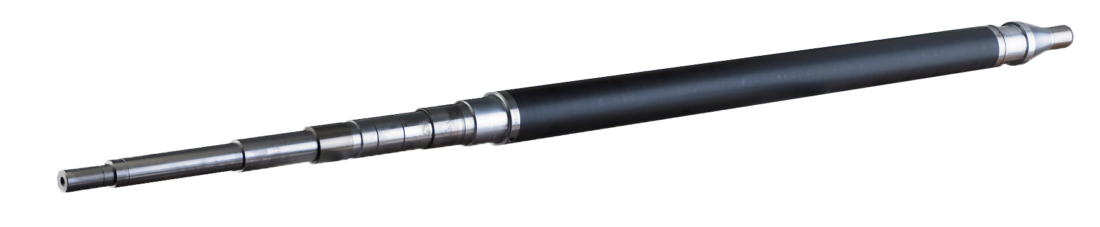

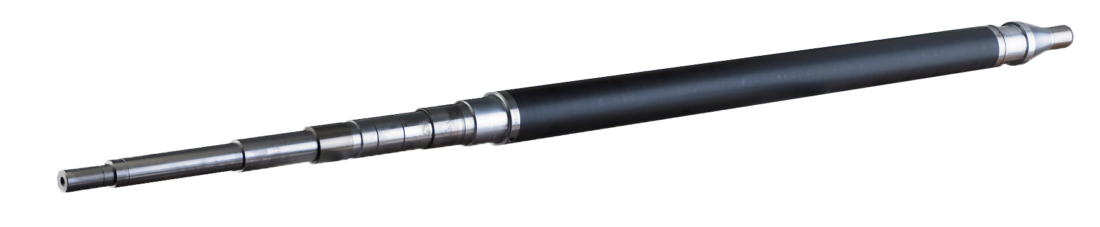

Carrier shafts (shafts)

Key components of flexographic printing machines, carrier shafts play a crucial role in print quality and productivity (reducing machine downtime and setup times).

Thanks to their lightness and rigidity, carbon fiber shafts offer enhanced performance compared to traditional metal solutions, with reduced inertia, better wear resistance, and improved energy efficiency.

CyKlon® Adapters: the sustainable solution for high-quality printing

To meet the needs of all printers, the CyKlon® carbon fiber sleeve range is available in 3 performance levels:

| CyKlon® Essential The CyKlon® Essential is the foundation of our range, but it is far from an entry-level product! The performance of CyKlon® Essential sleeves already surpasses standard carbon fiber products on the market, making them perfect for standard printing speeds while offering an optimized budget. | CyKlon® Evolution The CyKlon® Evolution are the most commonly used carbon adapters by our clients. They are suitable for demanding printing jobs (color gradients, large solid areas, numerous breaks, etc.) at high speeds (productivity/competitiveness). | CyKlon® Star The CyKlon® Star adapters are the highest-performing on the market. They are suitable for the most demanding printing jobs, combining technical specifications with high print speeds. |

Romain COULLETTE, Directeur Commercial

“Nos clients ont tendance à panacher les intercalaires CyKlon Evolution avec les CyKlon Star (la référence absolue en terme de rigidité) pour les couleurs les plus critiques”

Did you know that the performance of these critical components can vary by as much as double, despite having a similar appearance?

With a design optimizing rigidity, lightness, and durability, the CyKlon® range takes print quality to an unprecedented level thanks to K1 technology.

With over a thousand flexo presses equipped worldwide, our products are approved by the leading machine manufacturers and are highly regarded by printers who frequently adopt them as retrofit solutions to boost productivity and resolve print quality issues.

Good to know:

Flexography, also known as ‘flexo’, is an innovative printing method that uses a flexible plate to transfer ink directly onto various substrates such as plastic, metal films, cellophane, paper, or cardboard. Flexo printing is primarily used for packaging food and beverages.

The use of carbon fiber composites in central impression flexo presses (flexo CI) is becoming more widespread, from printing shafts to sleeve adapters, doctor blade chambers, and anilox rollers.

Printer’s testimonial:

CyKlon® Distributor Partners:

Mexico

Spain

Turkey

Allemagne

Germany

Poland